Compressor scrap is one of the most desirable and demanded metal wastes in the global recycling business. With the increasing demand for sustainable energy usage and green waste management, compressor scrap has become a top choice for recycling companies as well as metal traders. Compressors, being a common component in air conditioners, refrigerators, and industrial cooling systems, contain a mix of high-value metals such as copper, steel, and aluminum. These materials make compressor scrap a valuable source of recyclable material, driving demand locally and even internationally.

What is Compressor Scrap?

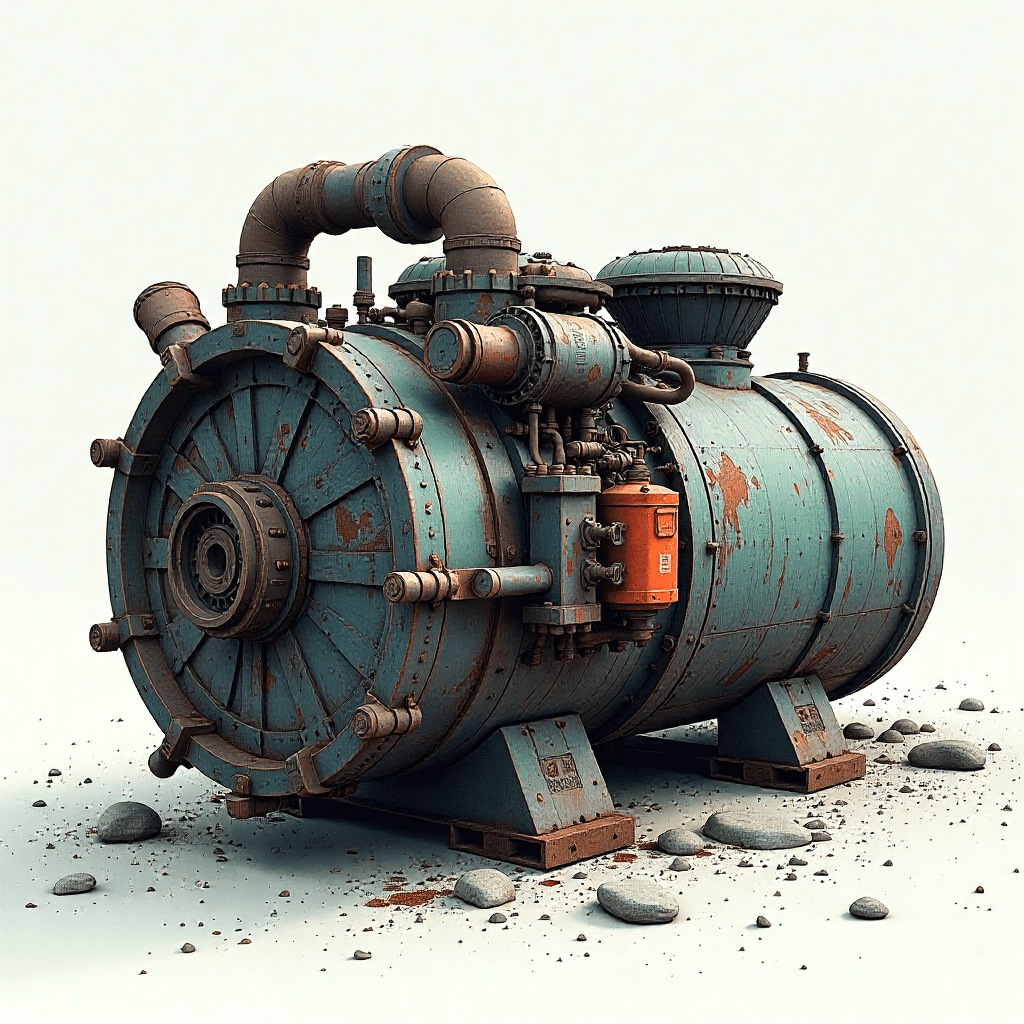

Compressor scraps refers to used or waste compressors that are no longer operational but have valuable metal and material content. Compressors are predominantly used in home appliances, air conditioning systems, refrigeration systems, and most industrial equipment. A compressor’s internal composition includes a motor, copper windings, iron casings, and aluminum components that can be salvaged through efficient recycling techniques.

In simple terms, compressor scrap is collected from old industrial equipment and appliances, broken down, and separated by the type of metal. This is with the goal of recovering recoverable metals, reducing waste, and working towards a circular economy where materials are recycled, rather than being wasted.

The Value of Compressor Scrap

One of the reasons compressor scrap is so highly sought after is that it contains a high rate of non-ferrous metals, specifically copper. Copper is one of the more precious metals on the recycling market, with it often commanding premium prices due to its high conductivity and versatility. Compressors also contain steel, which adds to the overall weight along with resale value.

For example, a single compressor of an air conditioner may contain several kilograms of copper and aluminum, making it a worthwhile unit for scrap dealers and recycling plants. Compressor scrap price may vary depending on the following:

Metal content (copper-rich compressors are more valuable)

Weight and size

Market value of copper, aluminum, and steel

Condition and contamination level

All these make recycling companies and dealers test and classify compressor scrap so that its actual worth in the market is determined before its sale to the export customers or refiners.

Compressor Recycling Process

The recycling of compressor scrap has a variety of procedures that ensure the metals are recovered safely and efficiently. The procedure generally involves:

Collection and Sorting: Used compressors are gathered from households, HVAC service shops, and manufacturing plants. They are sorted based on size, weight, and type.

De-gassing: Refrigerant gases must be safely evacuated from compressors before they are dismantled. These gases can be harmful to the environment and thus this step is necessary.

Dismantling: The compressor is disassembled manually or mechanically to remove copper windings, steel shells, and aluminum components.Compressors scrap

Shredding and Processing: The metals are shredded into tiny fragments to make them easy to handle and melt.

Melting and Refining: The various metals are melted separately in furnaces to be refined and prepared for reuse in new products.

By doing so, the recycling industry helps to conserve natural resources, reduce greenhouse gas emissions, and limit landfill waste.

Environmental Importance of Compressors Scrap Recycling

Recycling of compressors scrap helps to save the environment to a great extent. Mining and processing of virgin metals like copper and aluminum involve huge energy consumption and air and water pollution. Through recycling of scrap, energy consumption is significantly lower—up to 90% less in copper recycling.

In addition, proper recycling prevents the release of harmful refrigerant gases that are destructive to the ozone layer. When recycled in an environmentally responsible manner, compressor scrap recycling supports sustainable industrial development and is aligned with global efforts to mitigate climate change. scrap

Market Demand for Compressor Scrap

The world market for compressor scrap is growing fast, particularly in nations with large recycling markets such as China, India, the United States, and most of the European countries. All of these countries have large smelting plants that recycle imported scrap metals for use in construction, electronics, and manufacturing.

The developing countries are also becoming significant players in the compressor scrap trade, with local collectors and exporters hoarding used compressors for sale to overseas buyers. The consistent demand for copper and aluminum ensures that compressor scrap remains lucrative even in unpredictable markets.

As eco-friendly production gathers momentum and recycling takes a growing priority, compressor scrap has taken its place as a top-priority commodity in the scrap metal value chain across the world.

How to Identify Quality Scrap

Compressors are not all built the same, and knowing how to identify quality compressor scrap can make a significant difference in price. The following are some tips:

Heavier compressors generally contain more copper and iron content, making them more valuable.

Older-model compressors from industrial equipment will often have thicker copper windings.

Avoid oil-contaminated or gas-filled units, which can reduce resale value and cause extra handling.

Purchasers like to buy clean, sealed units as they are safer to ship and present fewer safety risks.

Dealers who can sort and prepare compressor scrap in a suitable way get more profit and also have good links with recycling companies or exporters.

Economic Opportunities in Compressors Scrap

Besides environmental benefits, recycling of compressor scrap has enormous economic value. Scrap scavenging provides thousands of small traders and laborers around the world with a livelihood. Recycling centers also provide jobs in metal manufacturing, transportation, and export.

Secondly, governments and bodies are now beginning to promote recycling as part of national sustainable projects, offering inducements and laws enforcing responsible management of scrap.

End

Compressor scrap is not only discarded machinery but a valuable commodity that fuels the recycling industry and promotes environmental sustainability. With its high copper and steel content, compressor scrap is a very lucrative proposition for collectors, traders, and recyclers. By understanding its value, the ways in which it can be processed, and the market dynamics, businesses can turn a once-waste product into a sustainable revenue stream.

Since the world’s industries continue to concentrate on recycling and green manufacturing, compressor scrap will remain an essential component of the metal recycling business. Investment in recycling and collection of it is not just beneficial for economic growth but also for the survival of the world’s finite resources for generations to come.